A latest research revealed in npj Versatile Electronics proposes a wi-fi stress monitoring system utilizing a 3D-printed origami stress sensor array. It’s geared up with customizable structure sensors to beat the boundaries of present business stress mats. This cost-effective and adaptable stress monitoring system can work within the 70 to 2500 kPa stress vary.

Background

Stress monitoring is important for people in bodily demanding circumstances equivalent to laborers, athletes, and elders. Stress knowledge acquired via monitoring methods and sensors can be utilized to establish biomechanical abnormalities, design ergonomic insoles for footwear, and improve sports activities coaching.

Just lately, quite a few efforts have been made to plan wearable stress monitoring methods with enhanced efficiency, measured when it comes to detection vary, sensitivity, linearity, sturdiness, and response time. Combos of assorted versatile substrates (for sensing) and conductive supplies (for electrodes) have been explored to optimize these parameters and develop piezoresistive, piezoelectric, and triboelectric stress sensors. Nonetheless, the present business stress sensors are constrained by dimension and sensing accuracy points.

The selection of fabrication approach additionally influences sensor efficiency. The widespread manufacturing strategies for stress sensors are categorised as force-based, electrical field-assisted, and light-assisted fabrication. These contain a number of advanced steps and require specialised gear and managed clear room environments, which will increase the ultimate gadget price. Furthermore, when a stress monitoring mat is broken, the complete gadget wants alternative. Thus, the researchers on this research used 3D printing to manufacture a versatile stress sensor array with a pillar-origami construction.

Stress Monitoring System Fabrication

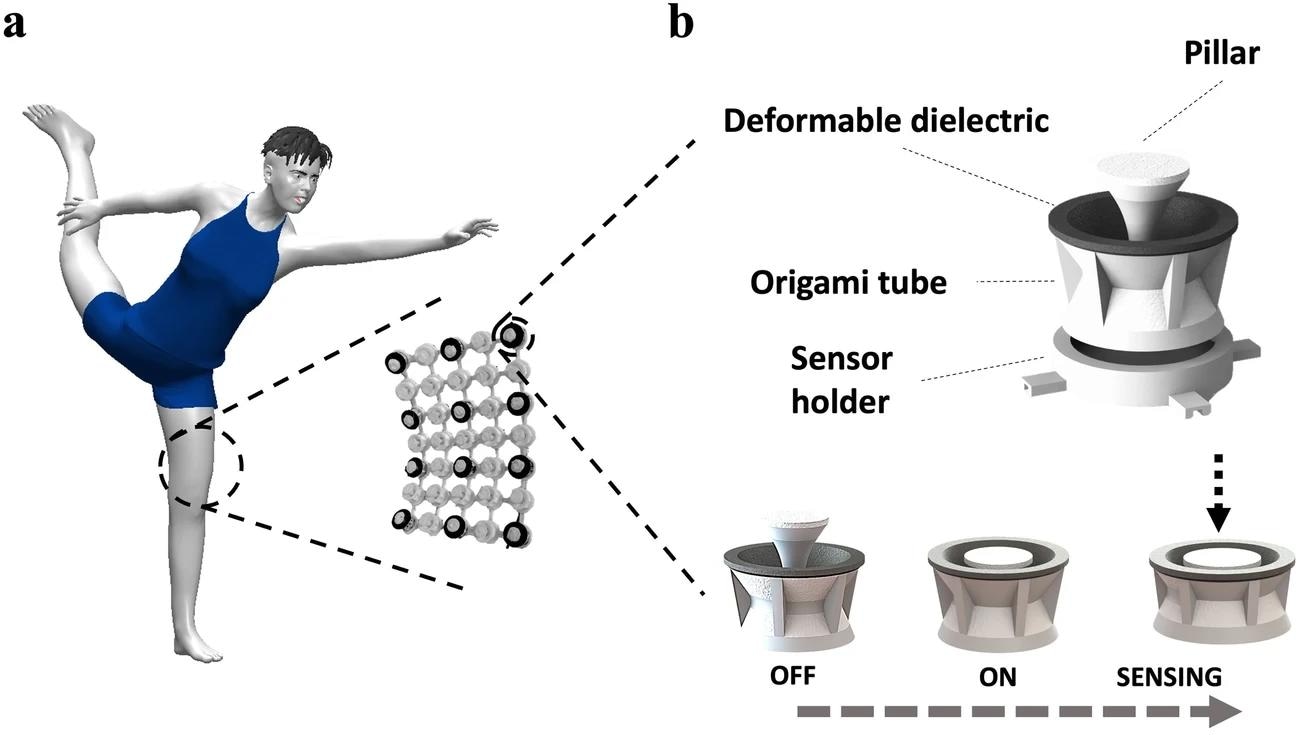

The researchers employed twin nozzle fused deposition modeling (FDM) 3D printing expertise, which permits simultaneous manufacturing of the sensor’s versatile construction and electrodes in a single step. Firstly, a 3D mannequin of the sensor was ready utilizing Stable Works 2022 software program, which includes two important parts: array and models. A fused filament fabrication 3D printer was used to print the array and models, adopted by the meeting of dummy/sensing models into the array.

Since this research aimed to plan a capacitive stress sensor, a separate dielectric construction was ready together with the bottom. The twin-structure design consisted of an origami tube strengthened with ribs and a central pillar. Furthermore, the applying of minimal stress on the sensor deforms its dielectric construction (after buckling of the pillar and origami half) and alters its capacitance. Human pores and skin was employed as one of many electrodes utilized in capacitance measurement to mitigate the human physique’s impact on gadget capacitance.

Two stress mapping mat gadgets have been designed and assembled utilizing the proposed methodology: a 150 × 150 mm foot stress mapping gadget and a 150 × 100 mm array for sports activities functions. Every gadget consisted of a stress mat, a reference electrode, an information acquisition board, and a 5 V energy financial institution for the information acquisition board. A MATLAB script was used to obtain wi-fi knowledge from the information acquisition board and contour plot the sensing knowledge.

The efficiency of each gadgets was evaluated in real-like situations. As an example, the foot stress mapping gadget was employed to document the stress contour utilized to the human foot (in 4 distinct postures) throughout bodily actions. One other gadget was positioned contained in the protecting pad of an athlete to measure the influence forces skilled throughout sporting actions.

Outcomes

The proposed stress sensor with pillar-origami construction supplied exact stiffness management, successfully filtering pores and skin deformations and enabling capacitive stress sensing. The proposed architectural design displays a finely tunable stress measurement vary from 70 to 2500 kPa with sensitivity between 0.01 kPa-1 and 0.0002 kPa-1 and a response time of solely 800 milliseconds. Moreover, the complete gadget is transportable and stress mapping will be monitored in real-time and on-line.

Form programmability is a vital characteristic of the fabricated 3D stress sensor as its mechanical properties will be managed by various the geometrical parameters. Thus, the stress vary and sensitivity of the gadget will be optimized by various the origami tube thickness, origami folding angle, pillar diameter, hole between the higher floor of the pillar and origami tube, and the variety of supporting ribs.

The FDM 3D printing expertise used within the research resolves adhesion points typically encountered in multi-layer sensors. It permits modification of the size, form, and determination of the stress mat in response to the person’s specs. As well as, the modular sensor array built-in into the stress monitoring system facilitates simple upkeep.

Conclusion

Total, this paper efficiently demonstrated a wi-fi stress monitoring mat that may overcome the adaptability and accuracy points within the present stress sensors. In case of harm inside the sensor array, it’s potential to exchange particular person sensing models as a substitute of the complete gadget, making gadget upkeep economical and sustainable together with prolonged operational performance.

With potential functions in wi-fi foot stress mapping and sports activities safety pads, the proposed stress monitoring system generally is a important milestone within the improvement of versatile and customizable stress sensor expertise.

Journal Reference

Moeinnia, H., Agron, D. J., Ganzert, C., Schubert, L., & Kim, W. S. (2024). Wi-fi stress monitoring system using a 3D-printed Origami stress sensor array. npj Versatile Electronics, 8(1), 1–8. https://doi.org/10.1038/s41528-024-00309-z, https://www.nature.com/articles/s41528-024-00309-z