Liqtra, a manufacturer of industrial 3D printers, has introduced its new 3D printer LIQTRAFX-7 Pro with multi-nozzle technology.

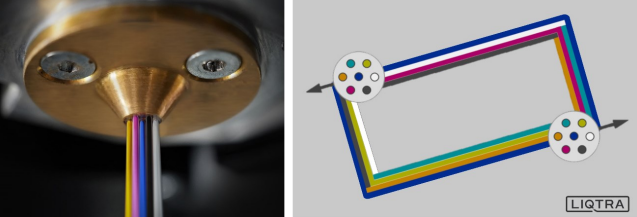

Patent-pending multi-nozzle technology is used in the LIQTRA FX-7Pro. Each nozzle can be controlled independently. It is said to increase productivity by as much as 300 percent and to improve part strength by as much 37 percent over a single or dual-nozzle 3D Printer, while maintaining the same level in geometric detail.

The LIQTRA planning software is used to manage the operation of this multi-nozzle slicer. This software uses artificial intelligence and mathematical optimization to determine the optimal part direction, set process parameters and plan individual control nozzles. Furthermore, Liqtra GmbH has collaborated with Sanitätshaus Köck & Dengl Orthotreff GmbH and PPprint GmbH to create a leg splint in less than 24 hours, reducing the single nozzle print time of nearly two days by a factor of four.

“The ability of the LIQTRA FX-7 Pro to produce larger medical aids overnight opens up new opportunities for quick and individual patient care,” said Florian Dengl (CEO of Orthotreff).

How will this new launch benefit customers?

LIQTRA multi-nozzle technology employs parallel extrusion to speed up the printing process. This is achieved by selecting the best active nozzles for each step and extrusion rate. This 300 percent productivity improvement is particularly important for meeting urgent printing needs that require small- to medium-sized parts to produce in a short amount of time.

Multi-nozzle 3D printing technology offers many benefits, including medical aids, customized manufacturing aids, fixtures and jigs, as well as small series production. The LIQTRA FX-7 Pro is capable of processing both PP (both fiber-reinforced). Liqtra has expanded its range of materials that can be processed to expand its reach for more applications.

Specifications and pricing

You can obtain pricing information from the company [email protected].

Closed-built Chamber x: 420mm; y: 300mm; z: 500mm

Materials PP, PA (also filled)

Filament diameter 1.75 mm

Layer height 100 μm – 300 μm

Check the temperature of your bed up to 120 °C

This link will take you to all of the information. Formnext news 2022.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter Follow us on TwitterLike our page or send us an email Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you interested in a job within the additive manufacturing sector? Visit 3D printing jobs For a list of available roles in the industry.

Feature image shows LIQTRA FX-7 Pro 3D printer. Image via Liqtra.