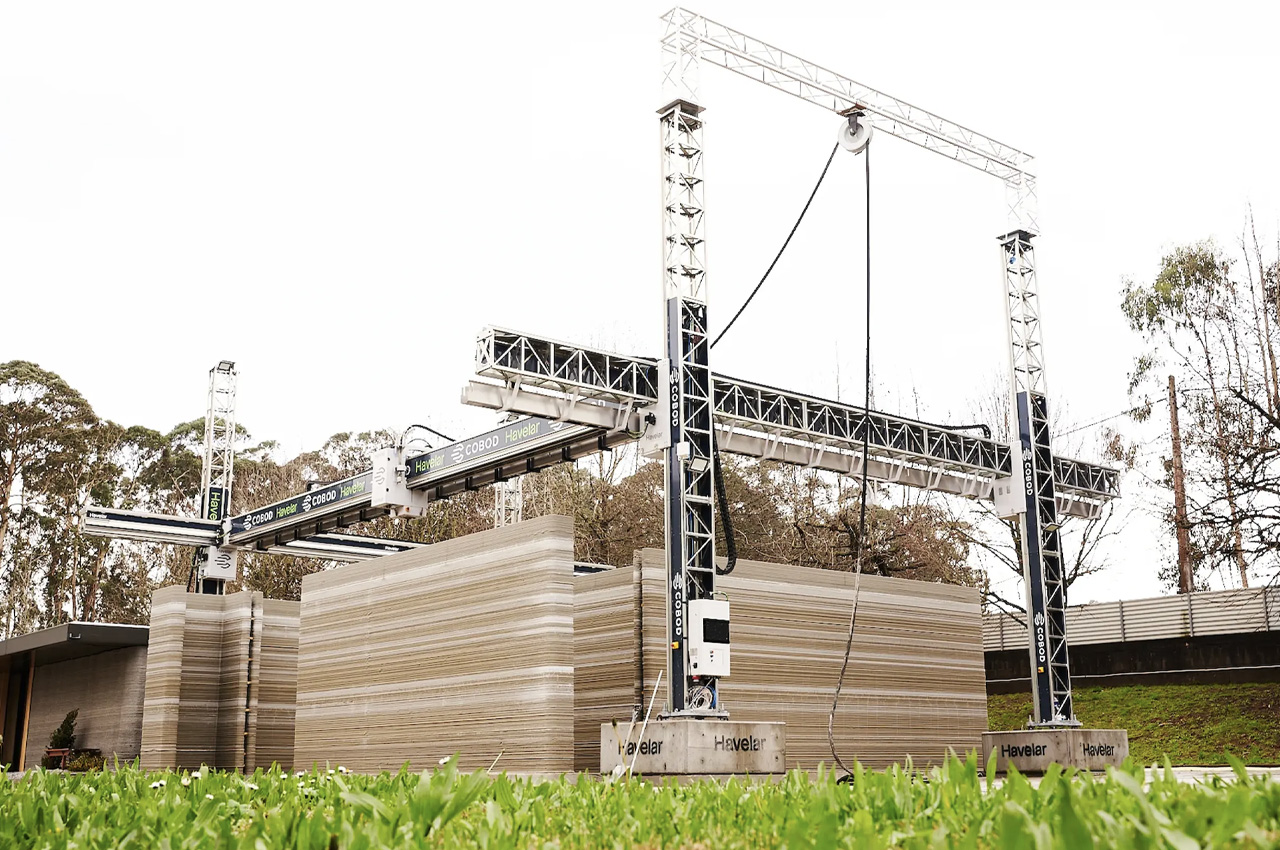

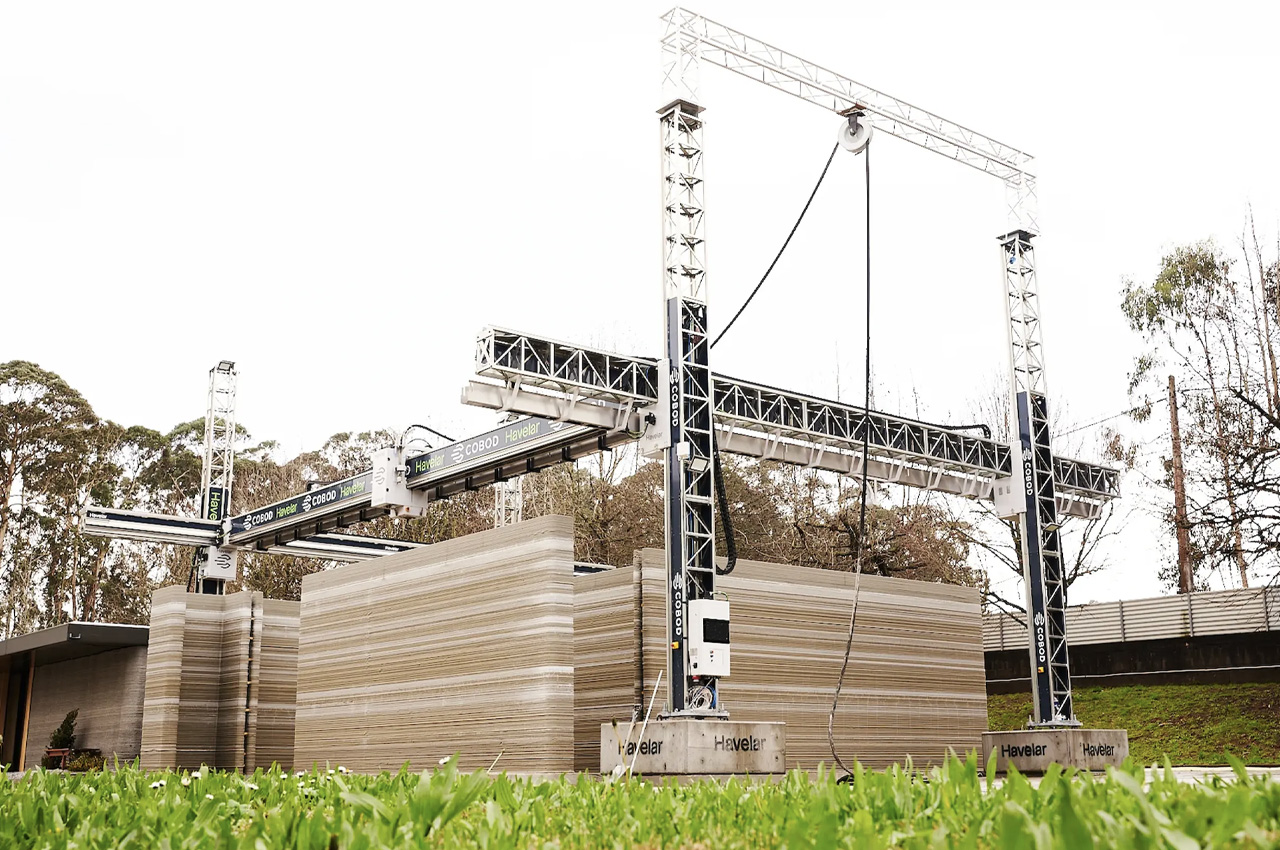

3D-printed structure has been making waves ever since its inception. It’s a improbable answer to expensive housing, offering economical housing choices to the inhabitants. Portagul-based Havelar is creating its very personal inaugural 3D-printed house, which takes solely 18 hours to print! The house is positioned within the Larger Porto space of Portugal’s second-largest metropolis. It’s designed to be an 80 sq ft two-bedroom residence which at present doesn’t have a reputation bestowed upon it. The house is printed utilizing COBOD’s BOD2 printer.

Designer: Havelar

The house may be constructed for €1,500 per sq m, which is a good deal compared to the Porto common of €3,104 (nearly US$3,330) per sq. meter. This economical price ticket is due to the pace of building supplied by the 3D printer. The printer follows a blueprint and types a cement-like combination from a nozzle in layers. This types the essential construction of the home. The printing course of takes nearly 18 hours, after which builders end the development by putting in the door, paneling, home windows, and roof. In addition they manually set up every other facilities which can be wanted. Taking the human labour into consideration, the house was accomplished inside two months.

The house by Havelar is a single-storey abode with telltale ribbed partitions which means that the house was constructed utilizing a 3D printer. The inside features a central kitchen and eating room, with two bedrooms, a front room, in addition to a rest room. The house is kind of fundamental and minimal in comparison with high-end and splendid 3D-printed properties you might have seen round, however taking the value tag into consideration it actually is a good deal for what you’re getting.

“We need to group up with companions who see themselves in constructing sustainable and accessible communities,” stated Rodrigo Vilas-Boas, Co-Founding father of Havelar. “With €150,000 [$161,000], it’s potential for a younger couple to have the house they’ve at all times dreamed of, in an space with good entry and providers.”

This house is the primary 3D-printed house developed by Havelar, however the agency plans to amp up manufacturing and even attain carbon neutrality by 2030, by shifting to different building supplies like straw and earth.