Better capability required for needlecraft and cross sew equipment provider

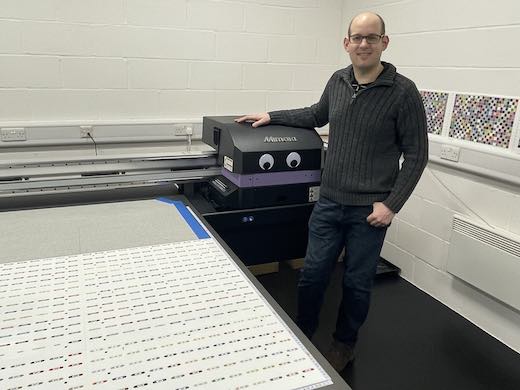

CMYUK, Shrewsbury: Gloucester-based Pip and Chip has bought a Mimaki JFX200-2513 EX flatbed from CMYUK. This 8 x4 ft, UV LED flatbed joins an current Mimaki UJV-6042 MKII printer and a pair of x Trotec Speedy laser chopping and engraving machines. Each Mimakis will share the workload of primarily printing acrylic bobbins that maintain all kinds of colored threads used for cross stitching.

Pip and Chip is the brainchild of husband-and-wife crew Craig and Debbie Wanstall. The transfer to a distinct segment printing enterprise was pushed by Debbie’s frustration along with her accountancy day job. Desirous to do one thing however undecided what, the couple bought a Trotec Speedy 350 laser cutter and put in it within the backyard shed.

They began exploring several types of merchandise, however ultimately determined that the World of Cross Sew may nicely be their oyster. This isn’t as random because it sounds, as though Debbie had dabbled with cross sew herself, mother-and-sister-in-law (each of whom now work for the enterprise) had been very proficient on this craft, which is a type of embroidery through which cross-shaped stitches are sewn in a tiled patterns to type an image.

The enterprise has been working for 5-years and for the primary three, produced ornamental thread holders – starting with a easy hedgehog-shaped bobbin initially minimize from MDF on the Trotec Speedy 360.

“It was only a flat piece that had some eyes laser minimize into it to make it look cute,” says Craig.

It was a crafting world success and earlier than lengthy the rise in demand for these ornamental merchandise led the couple to put money into further gear. A Roland UV printer was purchased to print varied formed thread and floss holders and joined by a Trotec Speedy 400 to satisfy the rise in chopping demand.

In April 2021, Debbie and Craig had moved the enterprise right into a small industrial unit. They began designing and producing their very own flat acrylic bobbins, printing on to the substrate to match the five hundred colors from world-famous thread and yarn provider, DMC, the go-to provider of the worldwide Cross Sew group.

Mimaki efficiency

The Roland UV printer was swapped out for a Mimaki 6042 MKII to realize a greater white and constant excessive constancy color matching.

“The white on the Mimaki is spot on due to the best way the ink circulates. It’s simply so good and stopped any yellowing or gray on our sheep bobbins,” says Craig.

Pip and Chip has fitted a robotic to the Mimaki 6042 MKII that robotically masses the printer 24 hours a day. “Nevertheless, we bought to the purpose with Robo (as we name it) that even that wasn’t sufficient. Often it goes unsuitable, and also you’d arrive within the morning and discover that no printing had been carried out in a single day after which you’ll be able to’t simply play catch up within the day,” he says.

The Mimaki JFX200-2513 EX was bought in June this yr to share the workload and hold abreast of the Trotec productiveness. Each Mimaki printers are used to print colors and numbers straight onto the acrylic bobbins that match thread that’s wound onto them.

All Bobbins are available a regular measurement (40mm x 40mm) and might maintain roughly 8 metres of thread. Measurement is necessary right here as bobbins are saved upright normally in particular drawer storage items. Pip and Chip additionally make the froth inserts that home them.

“We print onto the bobbins themselves with their quantity and the color, so whenever you put them in a drawer lined with foam, all of them look very fairly,” says Craig.

High quality correct color matching

Important to the entire Pip and Chip enterprise is color constancy. “As a colourblind man, I discovered methods to calibrate color precisely utilizing a spectrometer,” he says.

Craig makes use of a separate color administration server, the place all color processing takes place after which recordsdata are then despatched to the RasterLink RIP on the Mimaki.

The Mimaki JFX200-2513 EX prints 12 acrylic sheets at a time – offering an actual uplift to productiveness. Every sheet yields 84 Bobbins, and Pip and Chip has developed all its personal jigs.

Pip and Chip is a unusual enterprise and because of its explicit area of interest, has made variations to its Mimaki expertise. “Historically, we would not have appeared on the JFX 200-2513 EX as a result of it is actually a signage printer. Nevertheless, we’ve tailored it, turned all its high quality settings up, and slowed it down. It produces excessive definition and really correct colors. We’ve fiddled with it to get it simply how we wish it and it’s completely sensible,” says Craig.

Subsequent steps

Whereas highest high quality direct-to-substrate premium bobbin manufacturing will proceed to be the mainstay of the enterprise, till now Pip and Chip have offered these in units. Nevertheless, the enterprise has recognised a requirement for particular person colors and is presently exploring inventory management and fulfilment.

It additionally has plans to additional utilise its in depth color profiling expertise working its Mimaki gear to supply top quality, excessive tack stickers for different producers’ bobbins and thread storage programs.