How DTF printers can amplify product range and unleash new choices for signal store house owners

By Ginny Mumm

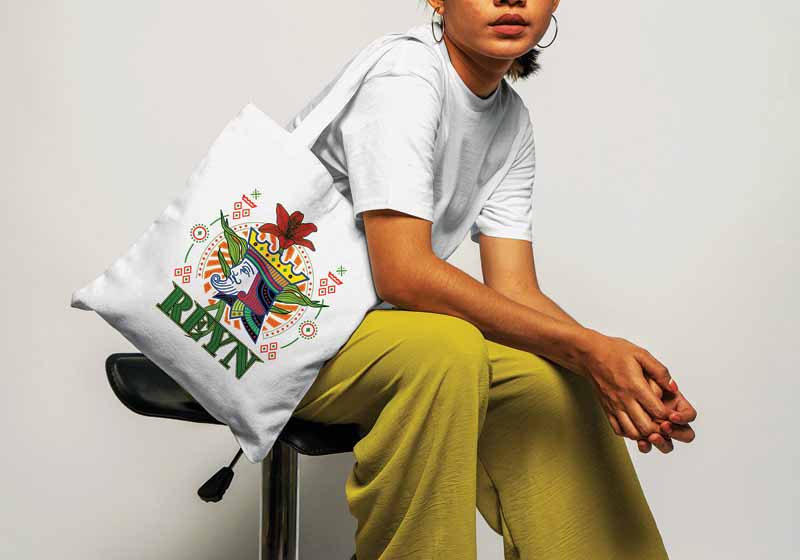

Including personalized attire can present a high-margin extra income stream for store house owners. Pictures courtesy Roland DGA

It’s no secret the market demand for customized attire is continuous to rise. The truth is, based on Grand View Analysis, the adorned attire market globally hit $28.98 billion (C$36.2 billion) in 2023, and is anticipated to develop at a compound annual progress fee (CAGR) of 13 per cent from 2024-2030.1

One of many quickest rising manufacturing strategies for customized attire printing is direct-to-film (DTF) manufacturing. DTF presents quick, high-quality manufacturing of one-off or short-run personalized attire merchandise. As soon as the province of attire producers and mall kiosks, these units are actually being built-in into signal outlets as a option to broaden product ranges and create customized attire in-house.

To seek out out extra about this widespread textile manufacturing technique, we talked with Roland DGA software specialist Mike Davis.

Why ought to print service suppliers (PSPs) take into account bringing attire manufacturing

in-house?

Mike Davis (MD): Signal store house owners right now are sometimes requested if they supply customized shirts, hats, jackets, and tote luggage. Many are outsourcing this manufacturing to a different store, shedding the chance to supply what might be high-quality, high-margin merchandise themselves. In the present day’s DTF know-how permits store house owners to deliver full-colour, on-demand customized attire manufacturing in-house.

Display screen printers are additionally benefiting from DTF know-how to print smaller runs or samples. Superior Raster Imaging Processor (RIP) software program can produce the identical color choices as display screen printing, together with half-tones, with a lot much less setup time.

How are producers addressing the market’s rising want for on-demand customized attire manufacturing?

With manufacturing orders, it’s potential to realize a a lot greater hourly output with right now’s DTF units.

MD: Producers are responding with environment friendly, inexpensive DTF options that may sustain with the wants of outlets for high-quality on-demand manufacturing. First-tier producers additionally provide wonderful service and assist that guarantee constant up-time for these units.

Fashionable DTF printers are compact and straightforward to make use of, and don’t require customers to pre-treat materials. The fundamental workflow has just a few steps. For instance, if you’re printing one 304.8 mm x 304.8-mm (12 in. x 12-in.) picture onto a tee-shirt, the method of printing the graphic onto switch movie, coating it with shaking powder, melting the powder below a warmth press for the advisable time on the advisable temperature, after which warmth urgent the graphic onto a garment and eradicating the movie backing might be as fast as 10 minutes.

With manufacturing orders, it’s potential to realize a a lot greater hourly output with right now’s DTF units.

What sorts of attire and textiles can DTF print on?

MD: DTF is a remarkably versatile manufacturing platform. Whereas most individuals are printing on merchandise product of 100 per cent cotton, DTF can be used to print on 100 per cent polyester in addition to poly blends, denim, and on some sorts of nylon.

The most typical software is on tee-shirts; nevertheless, DTF works equally nicely on tote luggage, aprons, caps, and sports activities shirts. It presents PSPs the possibility to broaden their product line for purchasers. As a substitute of simply providing sports activities banners, decals, and yard indicators, with DTF, a store proprietor can present jerseys, father or mother shirts, hats, and different sorts of workforce attire.

As a substitute of simply providing sports activities banners, decals, and yard indicators, with DTF, a store proprietor can present jerseys, father or mother shirts, hats, and different sorts of workforce attire.

What ought to PSPs search for in a DTF printer?

MD: It’s essential to search for a producer offering sturdy gear that may ship constant color and high-definition output over time. It’s additionally key to discover a firm that stands behind their units with an excellent guarantee. You need to guarantee your machine will carry out optimally for so long as potential, and that ought to you want a component or service, your producer could have components and assist out there.

Some DTF printers provide extra options to assist guarantee vibrant, detailed graphics. For instance, Roland DG’s DTF printer—the VersaSTUDIO BY-20—boasts developments that not solely maximize color richness and accuracy, but additionally make this compact but highly effective desktop machine extremely easy to function. The BY-20 can be used for conventional print and lower purposes in addition to for warmth switch graphics. Moreover, some producers provide the opposite DTF system parts wanted—the inks, switch paper, and powder—to supply customers with a whole answer.

What sorts of software program are producers providing for this market?

MD: Most DTF producers are actually together with RIP software program with their units. Further software program is required to create the artwork.

Roland DG’s VersaSTUDIO line is particularly designed to be straightforward to make use of. The BY-20 features a license for a model of FlexiDesigner in addition to RIP software program. This can assist with creating vector pictures which might then be despatched for outputting and permits for customers to import their design from different software program.

What function does sustainability play in DTF manufacturing?

Whereas most individuals are printing on merchandise product of 100 per cent cotton, DTF can be used to print on 100 per cent polyester in addition to poly blends, denim, and on some sorts of nylon.

MD: The power to print on-demand helps with sustainability. With DTF manufacturing, you don’t should inventory your prints or take care of massive inventories that will not promote. You’ll be able to produce precisely what your purchasers need, when they need it.

What do you see forward for DTF printing? What improvements are within the pipeline?

MD: I feel the marketplace for DTF will proceed to get stronger. It’s an accessible and inexpensive means for store house owners to broaden their product choices and meet extra of their purchasers’ wants in-house. The printers themselves will bear minor tweaks to additional improve print speeds. There may be a motion towards a four-printhead machine fairly than the present commonplace of 1 or two printheads.

There can even be enhancements coming with the manufacturing parts, together with inks, powders, and movies. Sizzling peel movie is changing into widespread now.

Specialty movies resembling glitter movies and glow-in-the-dark movies are being launched as nicely, so I anticipate to see enhancements in these sorts of supplies as they mature available in the market. I’ve additionally come throughout samples of textured impact movies, which we must always begin seeing extra of going ahead.

Ginny Mumm is a contract guide for digital inkjet printer/cutter supplier Roland DGA. For extra info, go to www.rolanddga.com.

Notes

1. Learn the Market Evaluation Report by Grand View Analysis right here: https://www.grandviewresearch.com/industry-analysis/decorated-apparel-market