While you purchase by means of hyperlinks on our articles, Future and its syndication companions could earn a fee.

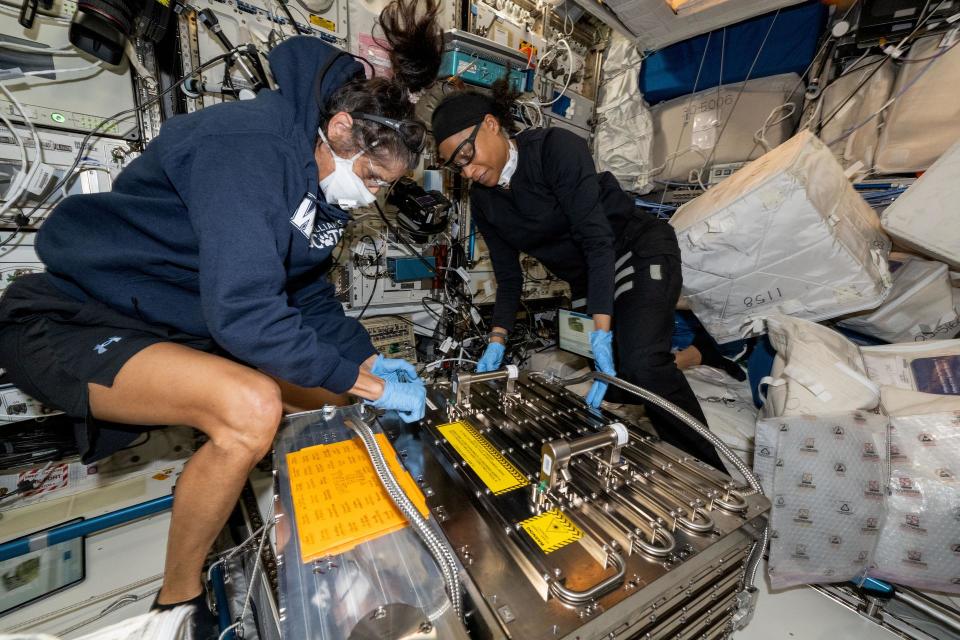

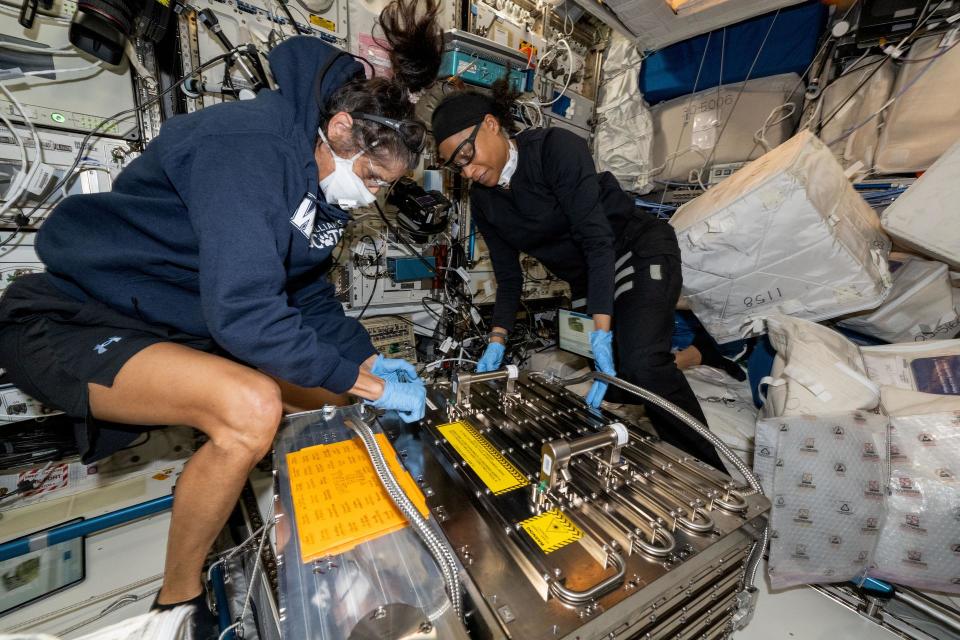

ESA scientists have efficiently demonstrated 3D printing of a steel half in house for the primary time.

3D printing in house poses challenges, as many strategies depend on gravity to place supplies in the course of the printing course of. It’s because when creating steel buildings, molten steel is commonly used as a part of the filament, or printable medium. In house, its habits might be unpredictable, which can lead to poor-quality objects, because the filament may shift or be positioned incorrectly as a result of lack of gravitational forces.

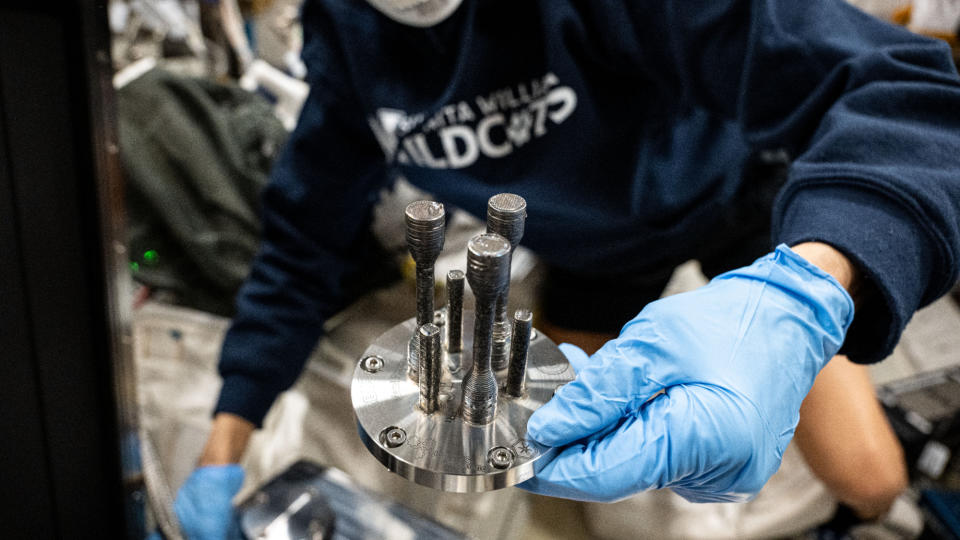

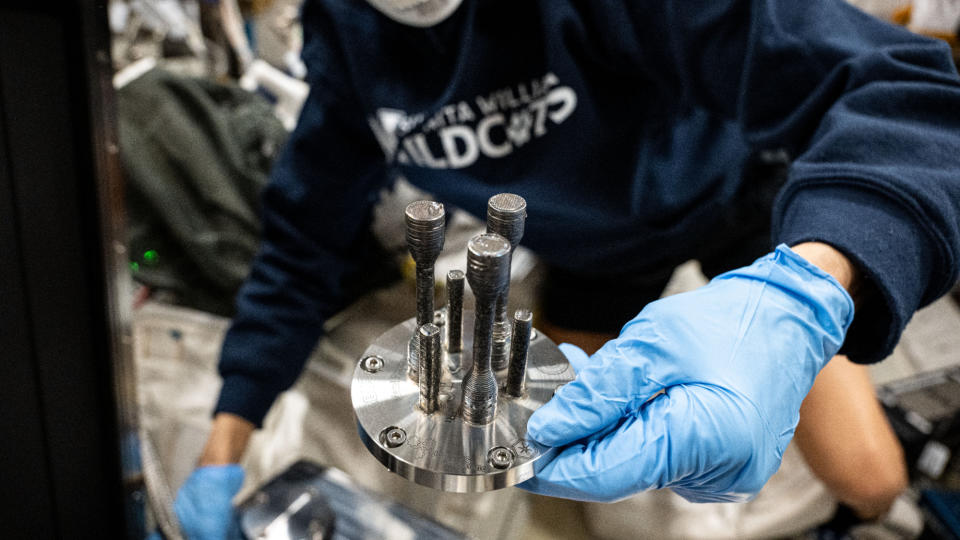

Scientists due to this fact needed to adapt to work underneath these difficult circumstances, and the Worldwide Area Station offered the proper setting. ESA’s steel 3D printer makes use of a chrome steel wire melted by a robust laser that reaches 2,192°F (1200°C) to create its molten steel filament that will get deposited layer-by-layer to construct out a desired form.

By means of painstaking assessments carried out over a number of months, the staff was lastly capable of regulate the printer to its microgravity surroundings, producing the primary steel half in house this August 2024. The staff plans to print two extra objects, then all three shall be introduced again to Earth for high quality evaluation and future planning.

Associated: Future moon astronauts could 3D-print their provides utilizing lunar minerals

“With the printing of the primary steel 3D form in house, ESA Exploration groups have achieved a major milestone in establishing in-orbit manufacturing capabilities. This accomplishment, made attainable by a world and multidisciplinary staff, paves the way in which for long-distance and long-duration missions the place creating spare elements, building parts, and instruments on demand shall be important,” mentioned Daniel Neuenschwander, director of Human and Robotic Exploration at ESA, in an announcement.

This groundbreaking know-how continues to increase its functions on Earth, revolutionizing fields resembling drugs, trend, artwork, building, meals manufacturing and manufacturing. In house, as long-duration missions to the moon and doubtlessly Mars take form, astronauts will want a way of independently repairing or creating instruments or elements for equipment or buildings that will be tough to hold onboard a spacecraft, which have restricted capability.

Because the know-how advances, it might even sooner or later allow the printing of latest tissues or organs, enhancing the power to maintain long-term house exploration—although we’re nonetheless a long time away from this being viable.

Associated Tales:

— 3D-printed hearts on ISS might assist astronauts journey to deep house

— A BFF in Area! Bioprinter Will 3D-Print Human Tissue on the Area Station

— Greatest space-themed 3D prints: Recreate iconic spacecraft and objects

3D printers in house are nothing new, as microgravity presents an attention-grabbing surroundings for scientists to conduct experiments, develop higher 3D printing supplies, or create buildings tough to make on Earth. Nevertheless, what’s vital about ESA’s latest announcement is that that is the primary time a 3D printer has efficiently produced a steel half.

This functionality represents a significant milestone as, till this level, steel parts for house missions needed to be produced on Earth and transported to orbit —a pricey and complicated a part of any mission.