Biomatters 3D print mycelium and clay as inside objects

New York Metropolis and London biodesign studio bioMATTERS mixes mycelium, clay, and home and industrial waste supplies to 3D print bio-digitally designed vessels and bowls. The household of inside objects glimpses on the potential of 3D printing to generate sturdy and recycled objects for properties and areas utilizing natural and waste supplies akin to mycelium and clay. bioMATTERS goals to create biodegradable merchandise with the doorway of its new sequence named MYCO-CLAY, adopting novel bio-fabrication workflows that mix mycelium, or fungal networks of entangled hyphae filaments, with earthenware clay, a pure sedimentary materials with excessive plasticity.

photos courtesy of bioMATTERS

Computational and generative design with 3D printing

bioMATTERS, a biodesign studio led by Nancy Diniz and Frank Melendez, says that the vessels and bowls replicate a up to date post-digital aesthetic. They arrive to life by means of computational precision, generative design, and 3D printing applied sciences, impressed by the biomechanical progress processes present in nature. bioMATTERS developed the vessels first. They used computational design decoding progress algorithms which gave them completely different morphologies for the design. Feeding the 3D printer with the generated design, the result recollects archaic, cavernous and petrologic vessels sprung to existence utilizing trendy 3D printing and computational applied sciences.

MYCO-CLAY vessel, computationally designed and 3D printed mycelium, clay, and upcycled waste supplies

bioMATTERS works on the bowls subsequent utilizing comparable strategies of computational design. Their foundations, nevertheless, emerge from conventional basket weaving strategies, and their layered, criss-cross patterns present up after being woven. A spread of weaving parameters was thought of by bioMATTERS earlier than they inputted the design into the 3D printer. The beading impact with variable protrusions of the bowls then makes its approach into the byproduct, having an analogous body and resemblance with their vessel siblings but asserting their distinctive characters portrayed by their digital woven patterns.

bioMATTERS fuses mycelium and clay to create 3D-printed bio digitally crafted objects

Mycelium grows over clay and waste supplies

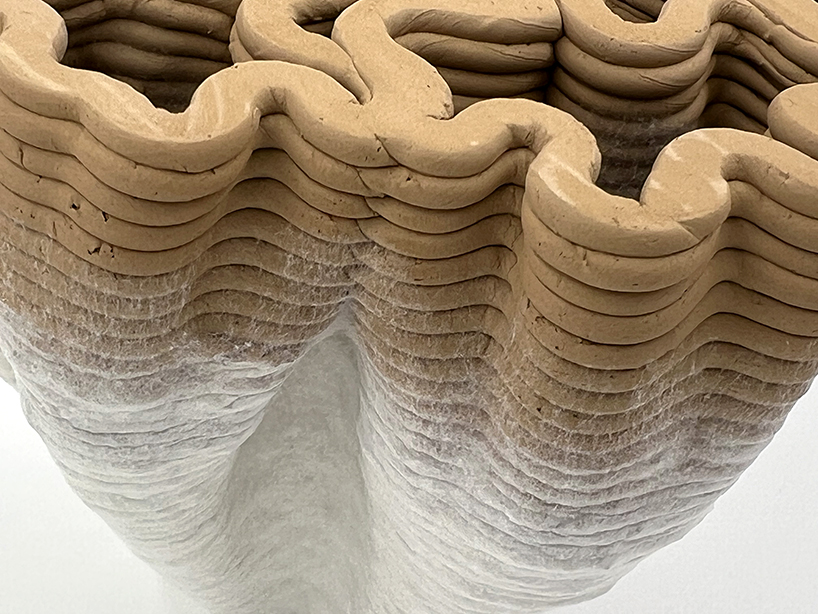

Given the pace of 3D printing and generative design applied sciences and processes, producing a number of items of those inside objects manufactured from mycelium and clay might be fairly fast. After being 3D printed, mycelium grows for a interval of 1 or two weeks till it grows and colonizes all through the vessels and bowls’ exterior. As time passes, the mycelium turns into denser and types a thicker tissue, making it appear like a community of spider webs. The ultimate items specific and let the pure progress of mycelium stand out as a bio-glaze over the terracotta clay and industrial waste supplies, all underlined by the sluggish commencement of their innate colours and textures.

MYCO-CLAY vessel, element

bioMATTERS says that mycelium and clay are plentiful and ubiquitous supplies. Mycelium, which is regenerative, might be cultivated and is taken into account one of many first terrestrial dwelling organisms to inhabit land. Then again, clay is a cloth utilized by people relationship again a number of millennia for making artwork, instruments, and structure, is plentiful lately and might be domestically sourced. The usage of home and industrial waste supplies to 3D print these vessels and bowls is to usher in upcycling and assist create a nutrient-rich substrate through which the dwelling mycelium grows. ‘The items are supposed to advertise a cultural shift in direction of design and fabrication with biomaterials whereas enhancing inside areas with a show of latest bio-aesthetics and bio-digital craft,’ says bioMATTERS.

MYCO-CLAY vessel, element.

MYCO-CLAY vessel, element.