The reproduction of animal muscle cells in vitro is what creates lab-grown meat. This process is a great way to provide ethical and eco-friendly meat for those who are concerned about the environmental or ethical concerns of the meat industry. Scientists from the National University of Singapore, National University of Singapore Suzhou Research Institute, China, and the Xi’an Jiaotong-Liverpool University, China have developed a new method to produce cultured meat (CM) of an appealing texture using new low-cost 3D printing inks as scaffolding.

Scaffold Material: Plant Proteins

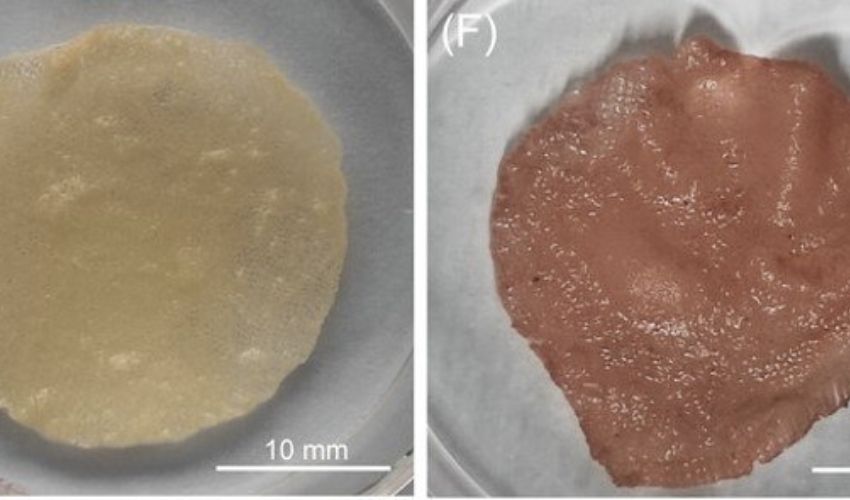

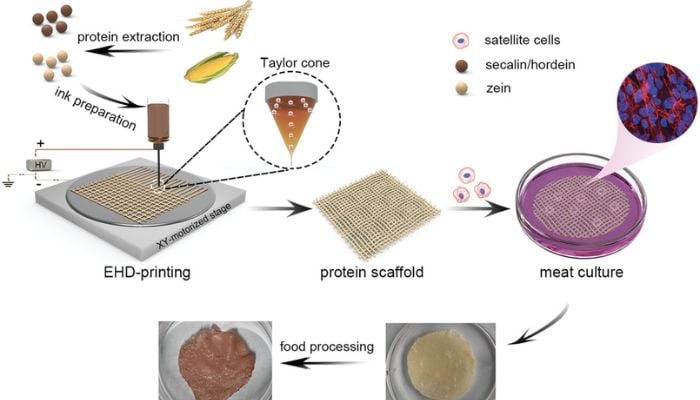

Research showed that skeletal muscles cells (bovine, porcine) were made using 3D scaffolds. These scaffold cells are crucial to maintain the product’s structural integrity. They also produce the best texture by separating layers of cells to allow for even growth. It does not have to be strong enough to absorb the meat, but it should be edible. Fibrous scaffolds ‘resemble the in vivo muscle tissue structure’ and are therefore of great potential in the production of CM. Researchers chose cereal prolamins (a group of plant storage proteins) present in ryes and cereals, to produce fully edible fibrous scaffolds, which they coloured with beet to improve the resemblance to meat.

Photo credit: Jie Sun/Xi’an Jiaotong-Liverpool University

EHD Printing was used for the scaffolds

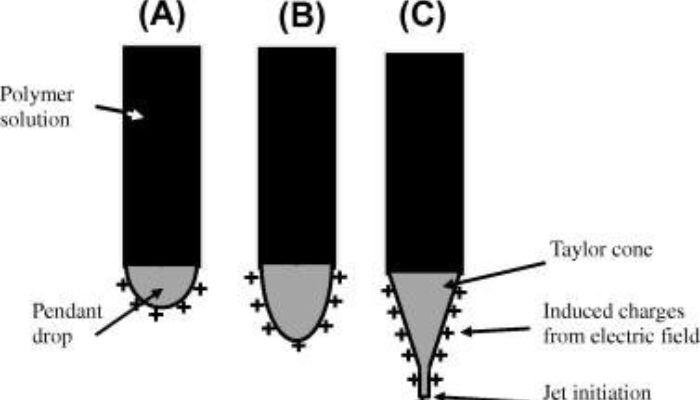

The scaffolds were produced using Electrohydrodynamic (EHD), printing by the researchers. This printing method is high-resolution. An electric field drives the printed liquid: The field causes mobile ions to accumulate in a polarizable fluid. The electric forces cause the meniscus, the curve at the container’s end, to become a Taylor cone. Stress caused by surface charge repulsion To be emitted liquid. Deposited droplets can have a diameter of as little as 240 nm and spatial accuracy as high as hundreds of meters.

Why is it important?

The 3D printing of inks was used to create fibrous scaffolds that were very effective in the production of cultured animals. Researchers discovered this. Professor Sun of the University of Xi’an Jiaotong-Liverpool University, China, summed up the importance of the experiment: “This is a novel and disruptive idea to mass produce cultured meat. Using nutrients from food waste to print scaffolds not only uses and increases the value of the food waste but also alleviates the pressure on the environment from animal agriculture.”

EHD printing: (C). The nozzle is ready to eject ink. (Photo credit to Neil Basson/Free quantity of electrospun organic–inorganic copolymers

“Currently, cultured meat’s high price is due to the lack of nutrient media for muscle cells. This is still derived from animal proteins. If suitable plant extracts are possible to provide nutrients, this will reduce the cost of cultured meat. MeatIt makes it more affordable.” Professor Sun concludes.

This experiment might remind you of similar schemes, for example 3D Treats’ cakes using FDM printing or Aleph Farms’ project to make 3D printed lab-grown steak. More information about this experiment can be found HERE.

Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.